In modern optical technology, uvlack lenses serve as fundamental components for focusing light and forming images, with their performance directly impacting the quality and efficiency of entire optical systems. However, the differing refractive indices of light at various wavelengths when passing through lenses cause chromatic aberration in imaging – a challenge optical designers have long strived to overcome. Today, we delve into an advanced lens capable of effectively addressing this issue: the near-ultraviolet achromatic lens.

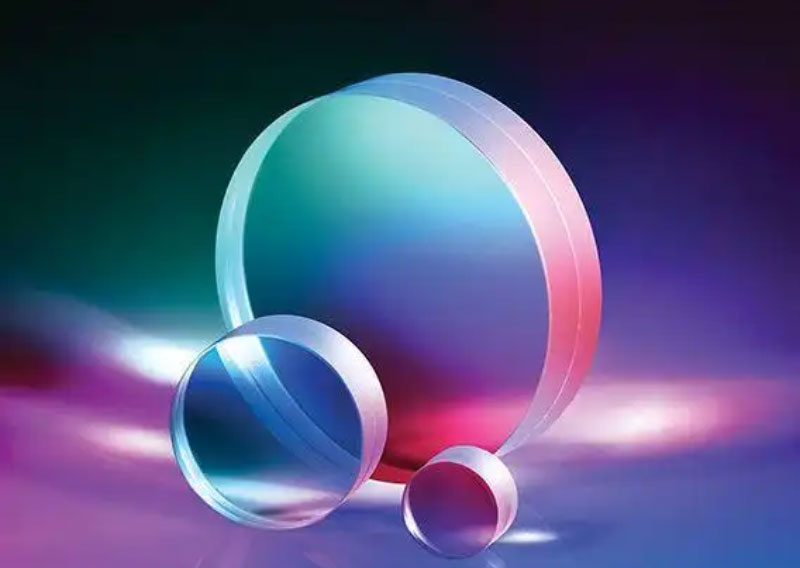

First, let us begin with the fundamental concept of an achromatic lens. As the name suggests, an achromatic lens is designed to eliminate or minimise chromatic aberration. Chromatic aberration, or dispersion, occurs when a beam of light containing different wavelengths passes through a lens. Because each wavelength is refracted to a different degree, they converge at different focal points, creating coloured fringes or halos that impair image sharpness and contrast. Traditional single-element lenses struggle to avoid this chromatic aberration. Achromatic lenses, however, utilise composite structures of multiple elements made from different materials. By leveraging the differing refractive indices of these materials for various wavelengths, they counteract chromatic aberration, achieving near-perfect imaging performance.

Next, we shall examine the characteristics of near-ultraviolet achromatic lenses in detail. These lenses are specifically engineered for the near-ultraviolet spectrum, typically spanning wavelengths from 300 to 400 nanometres. Within this range, many optical materials exhibit pronounced dispersion, leading to a significant deterioration in imaging quality. Consequently, near-ultraviolet achromatic lenses employ specially selected optical materials that demonstrate excellent transmission properties and relatively low dispersion coefficients in the near-ultraviolet spectrum. Through precise calculation and combination of these materials, chromatic aberration within the near-ultraviolet band can be substantially reduced or even eliminated.

To grasp this principle more intuitively, consider it analogous to teamwork in a relay race. Suppose each runner represents a different wavelength of light, and each team member’s speed represents the refractive index of different materials. Without coordination, faster runners (wavelengths with lower refractive indices) would surge far ahead of slower runners (wavelengths with higher refractive indices), much like how light produces chromatic aberration in ordinary lenses. However, by carefully selecting team members and distributing the baton to minimise speed disparities between runners, the entire team can advance at nearly identical speeds, ultimately reaching the finish line simultaneously. This mirrors how various materials interact within an achromatic lens to cancel out chromatic aberration.

In practical applications, uvlack near-ultraviolet achromatic lenses are extensively employed in scientific instruments and industrial equipment requiring high resolution and low dispersion, such as fluorescence microscopes, spectrometers, and lithography machines. In these contexts, accurate colour reproduction and sharp imaging are paramount. Take lithography machines as an example: these are employed in semiconductor manufacturing to precisely transfer circuit patterns onto silicon wafers. Should patterns become blurred due to chromatic aberration, it would directly compromise chip performance. Consequently, utilising near-ultraviolet achromatic lenses ensures precise pattern transfer, thereby enhancing both the success rate and efficiency of chip production.

Furthermore, the design and manufacture of uvlack near-ultraviolet achromatic lenses constitute a highly intricate and technology-intensive process. Designers must consider multiple factors including material properties, cost, and machining complexity. They typically employ sophisticated computer algorithms to simulate light propagation, optimising lens geometry and material composition. During fabrication, each lens demands exceptional machining precision; even minute imperfections can degrade imaging quality. Consequently, these lenses embody not only advanced design principles but also represent the pinnacle of precision manufacturing technology.

Finally, with the continuous advancement of technology, the application prospects for near-ultraviolet achromatic lenses will become increasingly broad. In fields such as astronomical observation, biomedical imaging, and precision measurement, the demand for high-definition, low-dispersion optical systems is growing steadily. This necessitates optical designers to continually innovate and develop higher-performance achromatic lenses to meet the challenges of future technologies.

In summary, uvlack near-ultraviolet achromatic lenses represent highly efficient optical components. Through ingenious material selection and design, they effectively resolve chromatic aberration issues within the near-ultraviolet spectrum. The development and application of this technology not only enhances the imaging quality of optical systems but also brings revolutionary advancements to scientific research and industrial production. As optical technology continues to evolve, we have every reason to believe these lenses will assume an increasingly pivotal role within the future landscape of optics.

optlenses

Related posts

What is Optical Burst Switching?

Activity 11 Optics Of The Human Eye

What is The Surface Area of This Rectangular Prism Brainly?

How to Get Super Glue Off Eyeglass Lenses?