Optical Lenses In the constant growth of the optical industry and the increasing demand for optical lenses keeps rising. The optical lenses are made into a variety optical lenses such as filters, reflectors and filters. attenuators and optical prisms optical lenses, and more. How are these optical lenses transformed into optical items? We will explore optical lenses by examining their processes. The optical lens processing process is separated in two categories: optical cold processing, and polishing of optical lenses.

1.Optical Lens Cold Processing

Optic cold processing: The goal of polishing the optical lens is to remove rough materials from the exterior surface of the lens, so that the lens will be a model in the beginning.

Once the polishing process is complete The optical lens is then finely polished to determine the R-value, and get rid of any surface impureness.

After two polishing processes The optical lens is polished to ensure that the lens will appear elegant.

Once the polishing procedure is finished the optical lens is cleaned, mostly to get rid of certain impurities from the lens following the grinding process and before polishing.

Once the dust on the lens’s surface is removed The grinding edge process begins for polishing the optic lens in accordance with the outer diameter of the lens.

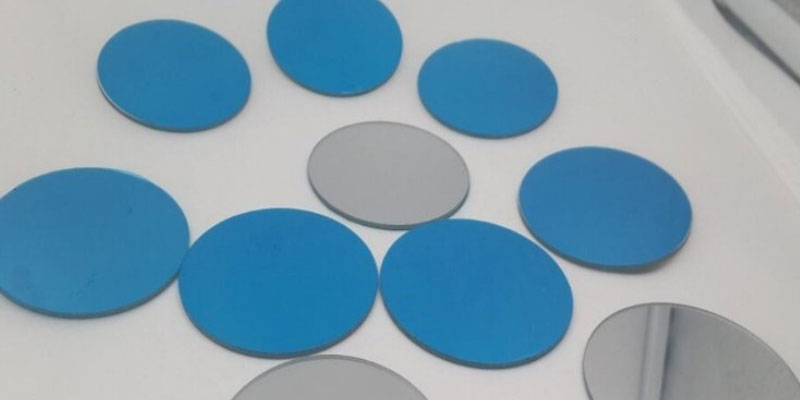

When the edge grinding process is complete and the optical lens has been coated in a variety of colors. The lens can be coated with one or more layers of film, as needed.

Once the coating process is complete, ink is placed on the lens. It helps to block reflections of the lens by simple applying black ink on the edge of the lens.

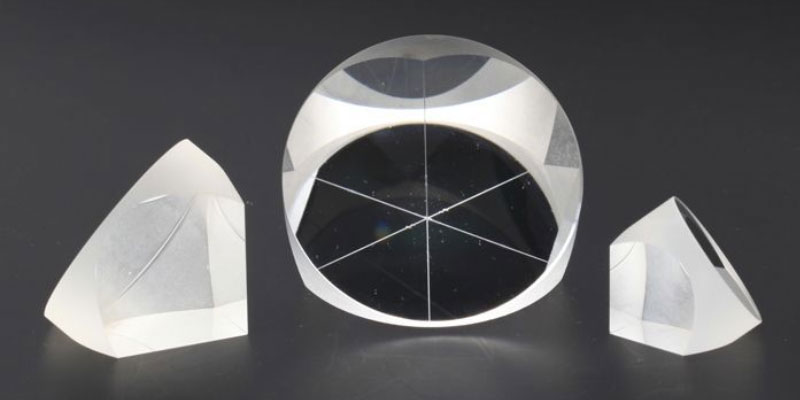

When the inking of optical lenses is finished The final phase of optical cold work, i.e. combination, begins. The two lenses are attached using the use of a specific glue. The R-values of both lenses should be the same but keeping the dimensions and diameters of the lenses equal.

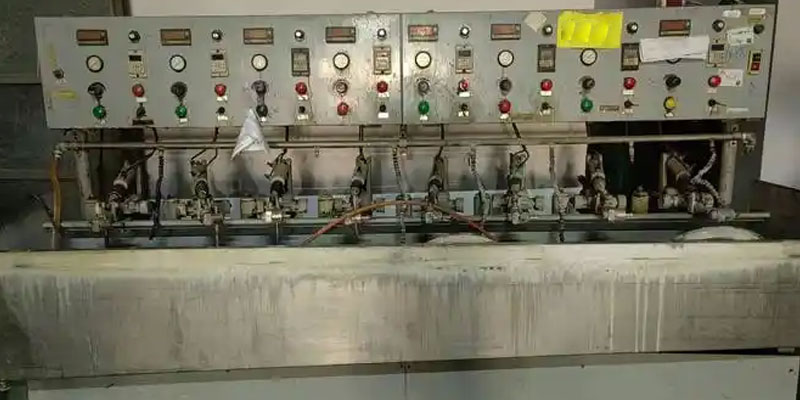

2.Polishing of Optical Lenses

It is necessary to use a polishing machine together with a polishing powder. During the polishing process, some parameters used in the polishing process shall be determined, such as polishing time and optical lens polishing pressure. After the polishing operation is completed, the optical lens should be cleaned quickly, otherwise some polishing powder will remain on the lens and cannot be removed. Optical cold working and cylindrical lenses also require attention.

optlenses

Related posts

what germanium lens is used for?

What Is Polarizer Film?

Porro Prism vs Roof Prism Lens

Dielectric Mirror Materials And Their Applications