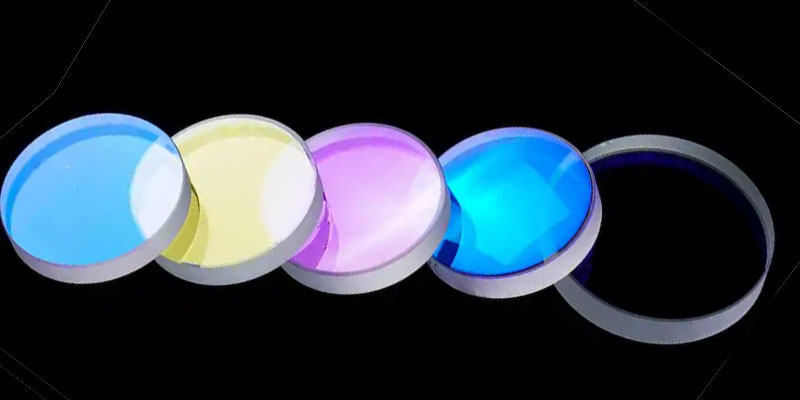

Primerem optical lens coating is primarily employed to enhance the optical performance of lenses, including increasing transmittance and reducing reflected light. The process typically encompasses preliminary lens cleaning, selection and preparation of coating materials, the coating operation itself, and subsequent quality inspection.

1.The Role of Primerem Optical Lens Coating

Primerem optical lens coating is a crucial process that significantly enhances the optical performance of lenses. Firstly, coating increases the lens’s transmittance, allowing more light to pass through and thereby improving imaging quality. Secondly, coating reduces surface reflections, minimising stray light interference in imaging. Furthermore, coatings protect the lens surface against scratches and corrosion, thereby extending the lens’s operational lifespan.

2.Process Flow for Primerem Optical Lens Coating

(1)Preparatory Work:

Prior to coating, the lens undergoes thorough cleaning to ensure the surface is free from contaminants such as oil residues and dust. This cleaning process typically employs specialised cleaning agents and pure water, often utilising an ultrasonic cleaning machine.

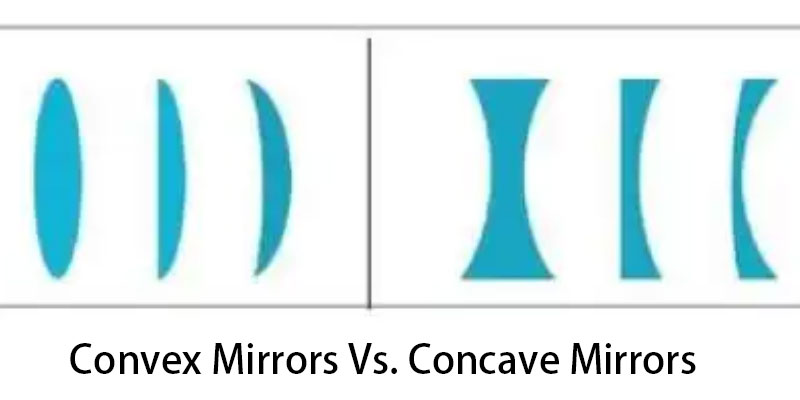

(2)Selection and Preparation of Coating Materials:

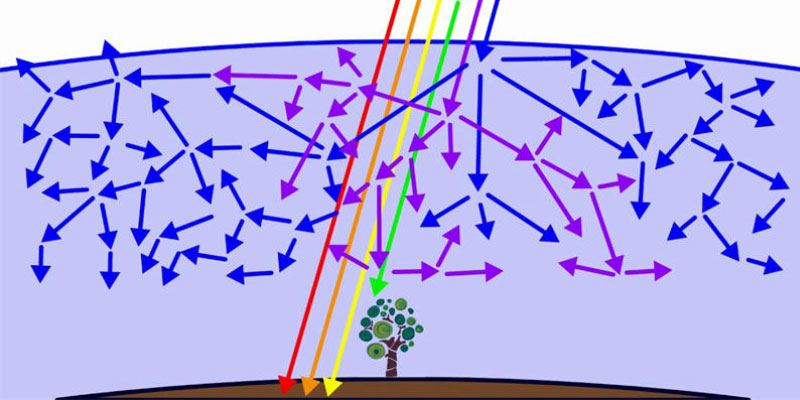

Appropriate coating materials are chosen based on the lens’s intended application and required optical properties. These materials, typically metal oxides or fluorides, form a uniform, transparent film on the lens surface.

(3)Coating Operation:

Place the cleaned lenses into the coating apparatus. Following vacuum evacuation, introduce an appropriate quantity of coating material. By precisely controlling parameters such as temperature and pressure within the coating apparatus, the coating material is deposited uniformly onto the lens surface, forming an optical film. This process demands exacting control of all parameters to guarantee coating quality and uniformity.

(4)Post-processing and Inspection:

Following coating completion, lenses undergo subsequent treatment and testing. Processing includes cooling and curing steps to ensure coating stability and durability. Inspection involves optical performance testing of coated lenses, such as measuring transmittance and reflectance, to verify compliance with design specifications.

In summary, opt lens coating represents a vital technology that significantly enhances both the optical performance and service life of lenses. By understanding the process flow and function of optical lens coating, we can better appreciate the intricate artistry of this technique.

optlenses

Related Blogs