The production of optical lens

The manufacturing process for optical glass typically involves the process of preparation of raw materials and melting, moulding, the annealing process and inspection. The following is a comprehensive outline of these processes:

1.Raw Material Preparation

Preparation of raw materials is the initial step in the production of optical glass. Based on what optical characteristics and compositions are desired, suitable raw materials like silicates, borates and silicates, phosphates and so on. are picked, and then accurately balanced and combined. In addition it is essential to add the correct amount of auxiliary substances like clarifiers and fluxes should be added to enhance the melting properties and quality of glass.

2.Melting Of Optical Lens

The process of melting is making raw material melt into liquids at a high temperatures. The raw materials mixed together are placed in the melting furnace and then heated at a high temperature in order so that they melt. In the process of melting certain parameters like furnace temperature, atmosphere and stir speed must be controlled to ensure the homogeneity as well as durability of the solution. Regular analysis and sampling is required to observe variations in composition as well as physical properties of the glass liquid.

3.Annealing Of Optical Lens

It is the method of transforming the molten glass into optical parts that are of the shape and size that is desired. Based on the desired shape and requirements, the appropriate moulding techniques are chosen including pressing, casting and drawing. In the process of moulding the parameters like temperature, pressure, and speed of the moulding machine must be monitored to ensure accuracy of the size and shape of the optical component. Regular checks and measurements are also necessary to observe the quality modifications of optical components.

3.Forming Of Optical Lens

Annealing involves gradually cooling the optical component that was moulded. In the process of annealing, variables like temperature gradient and cooling rate are to be managed to prevent the formation of stresses and imperfections inside the optical element. Annealing enhances the reliability and stability of optical components, and also ensures that they possess excellent mechanical and optical properties when used.

3.Inspection

Inspection is the final stage in the process of making optical glass. Inspection and testing must be rigorously conducted on the optical components, such as visual inspection as well as optical performance testing, and the list goes on. Inspection is a way to ensure that the optical components is in line with the standards, and that they are properly classified and labelled for future use.More Detail To Contact Us.

optlenses

Related posts

What is uses of concave mirror?

what germanium lens is used for?

What Is Polarizer Film?

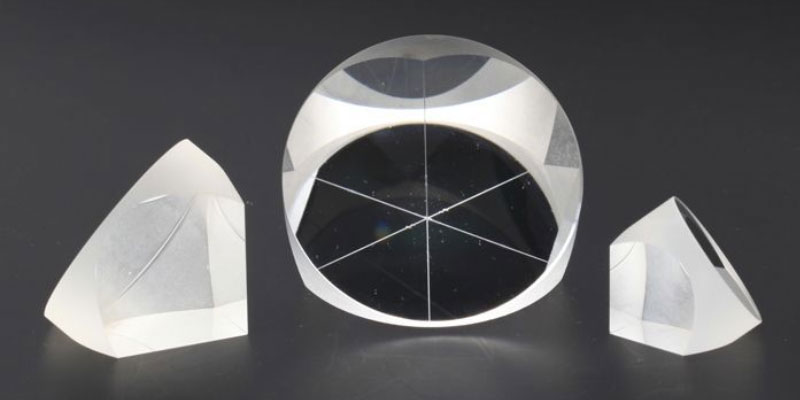

Porro Prism vs Roof Prism Lens