I. Basic Principle of Optical Lens Polishing and Grinding

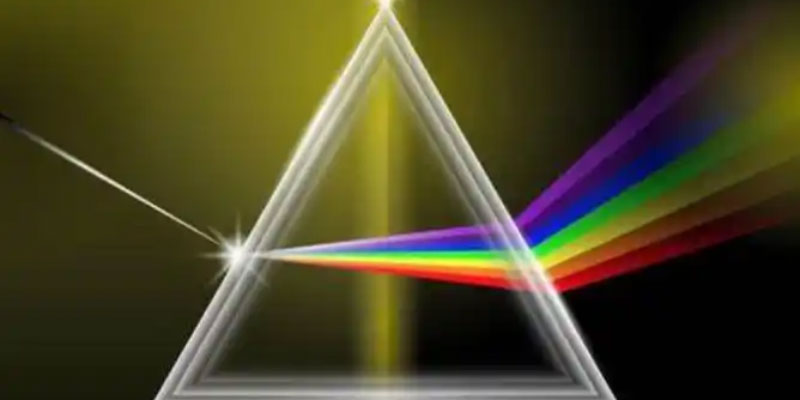

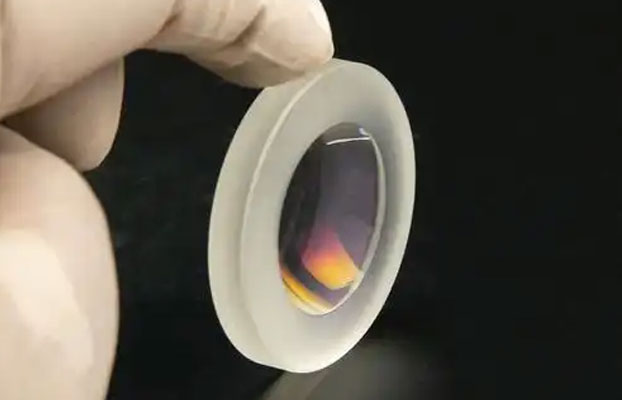

The fundamental principle behind grinding and polishing lenses is to utilize abrasives in order to grind the lens’s surface to eliminate surface imperfections and roughness and so that light is more pure when it passes across the lens. Grinding and polishing remove the small bumps and depressions found on the lens’s surface and ensure that light doesn’t scatter when it passes across the lens thereby increasing the optical clarity and transparency and performance of the lens.

2. The common tools and methods of optical lens polish

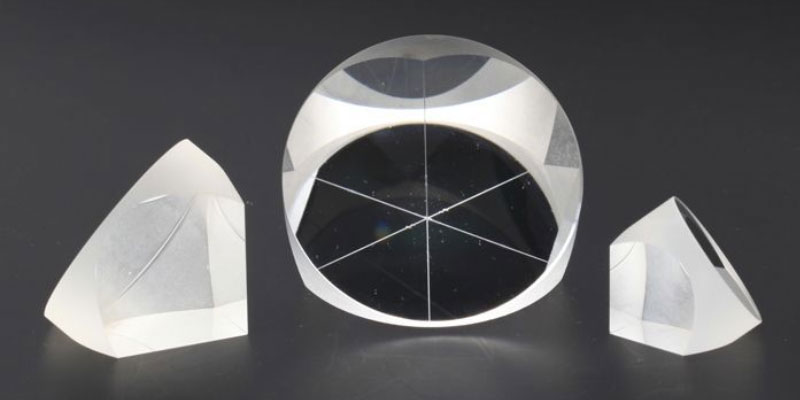

The principle behind a Spherical lenses is primarily based on two principles of optics, reflection and refraction. If light travels through a spherical lens because of the spherical design that the lens has, light will be refracted within the lens, thereby changing the direction of its propagation. In addition the spherical design of the lens may also decrease reflection of light and increase the effectiveness in light transmission. The exact process of light transmission can be determined by Snell’s law.

- Paper for grinding

Abrasive papers are among the most popular polishing tools. It is most commonly used with coarseness numbers #800, #1000, $1500 and the like. When employed in this manner, the abrasive sheet is fixed to an even platform, afterwards, the lenses are positioned on the paper, which is then gently sanded until the lens’s surface is flat and uniform.

- Abrasive

Abrasive is among the primary tools to polish and grind lenses generally made of iron oxide, aluminum oxide silicon oxide and various material that is granular. If you are using it abrasive, apply it evenly across the lens’ surface and then utilize the grinding machine to smooth it out.

- Polishing paste

The polishing paste will be the product that is used to finish the polishing of the lens. It is generally employing materials like iron oxide or chrome oxide. The lens’s surface is coated evenly with polishing paste, afterwards, it’s polished with an flannel or cloth wheel until the lens’s surface is shiny and clear.

3.Safety precautions when grinding lenses and polishing

- Polishing and sanding require precise and skilled machines and equipment.

- Be aware of your lens’s temperature while polishing or sanding, to avoid overheating. This could cause damage or even rupture.

- Lens polishing needs to be frequently evaluated and checked to ensure that it meets optical specifications.

Conclusion

Optical Lens Polish is a crucial process in the production of top-quality lenses. With the help of tools and methods like abrasive papers, polishing paste and abrasives, the roughness and unevenness of the lens’s surface is eliminated and the clarity and efficiency of the lenses will be enhanced. Pay attention to temperature as well as the precision demands of the optical lens during the process of grinding and polishing to ensure a cleaner lens is created.

optlenses

Related posts

What Is Polarizer Film?

Porro Prism vs Roof Prism Lens

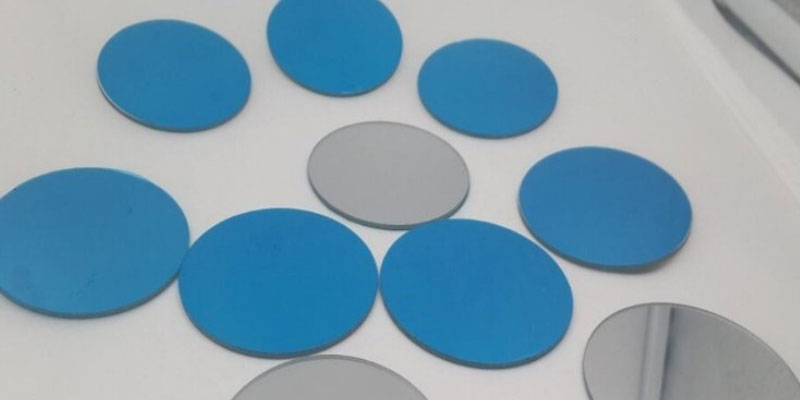

Dielectric Mirror Materials And Their Applications

What is the group velocity dispersion?