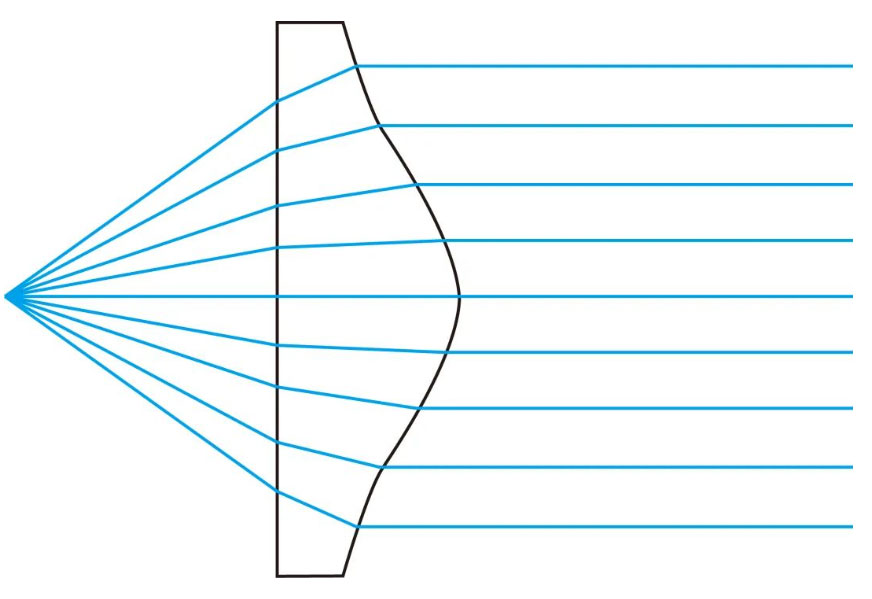

I. Working Principle of Optical Collimating Lens

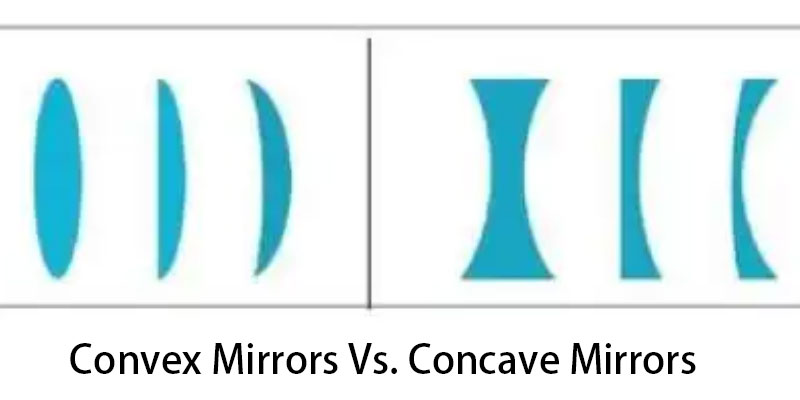

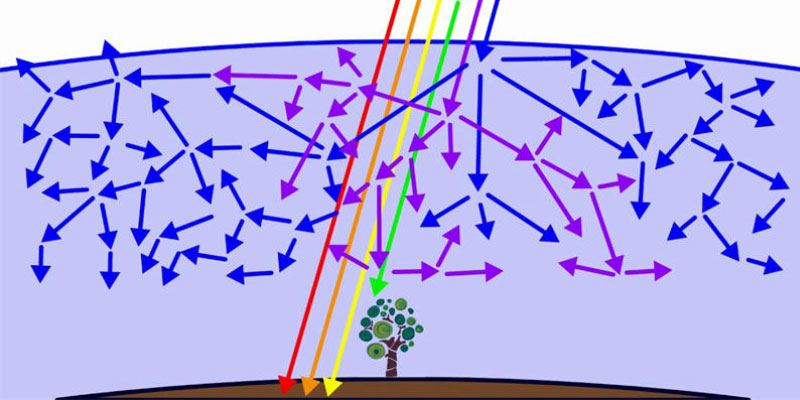

The core function of a collimating lens is to adjust the direction of light beam propagation through the principle of refraction. When a diverging light source (e.g. laser diode or fibre optic output) passes through the lens, the curved surface design of the lens redistributes the propagation path of the light so that the light rays tend to be parallel. This process is dependent on the focal length and radius of curvature of the lens:

Focal length selection: The shorter the focal length, the better the lens is able to compress the divergence angle of the light beam, but too short a focal length may lead to aberration problems.

Material properties: Commonly used materials include fused silica (high temperature resistance, low coefficient of expansion) and optical glass (lower cost), with infrared materials such as Calcium Fluoride (CaF₂) available for special scenarios.

Coating technology: Transmission enhancement coatings can reduce surface reflection losses and improve light transmission to over 99%, while customised coatings can also be adapted to UV or IR wavelengths.

2. Typical applications of collimated lenses

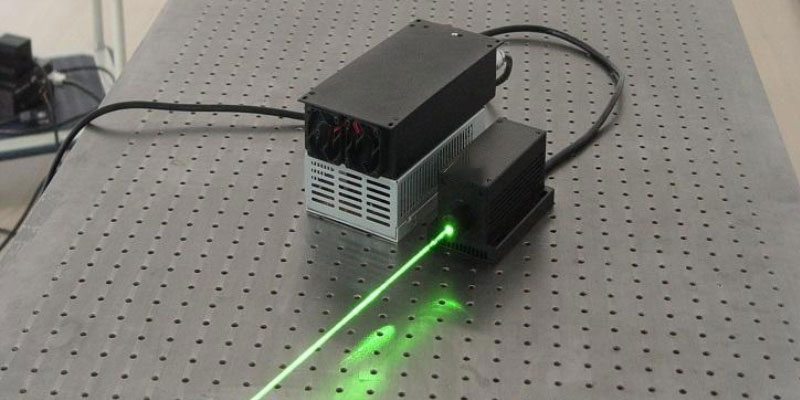

- Laser Processing and Manufacturing

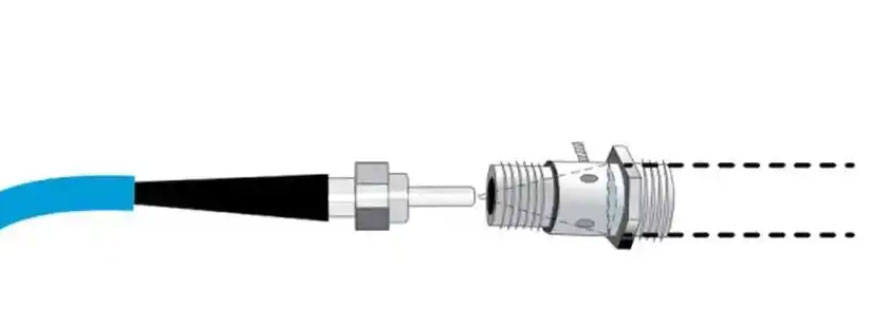

In laser cutting, welding and 3D printing, collimating lenses are used to ensure high energy density and parallelism of the laser beam to reduce processing errors. For example, the light output from a fibre laser needs to be calibrated by a collimating lens and then focused to achieve micron-level precision processing.

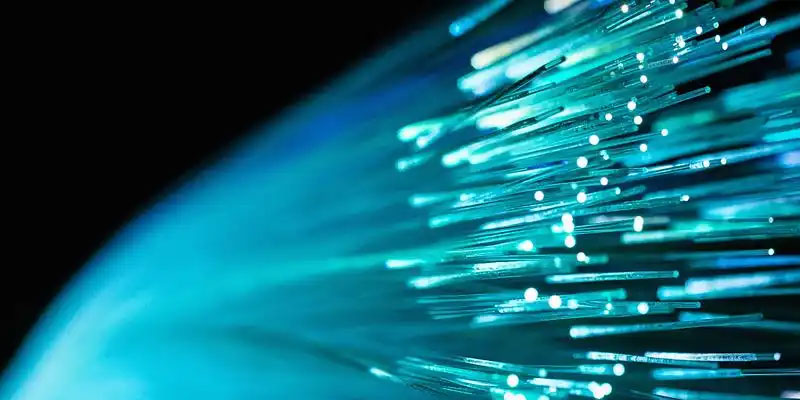

- Optical Fibre Communication System

Optical signals are prone to divergence in fibre optic transmission due to bending or connector problems. Collimating lenses can repair the quality of the light beam and improve the stability of long distance transmission. In addition, they play a key role in coupling optical paths in optical modules (e.g., optical transceivers in 5G base stations).

3.Medical and Biological Imaging

Devices such as endoscopes and confocal microscopes rely on collimating lenses to control the illumination path and ensure imaging clarity. Medical lasers, such as those used in eye surgery, also require collimation technology to precisely control the range of action.

Research and Testing Instruments

In precision instruments such as spectrometers and interferometers, collimated lenses are used to calibrate the light source and prevent stray light from interfering with experimental results. In the field of automatic driving, LiDAR system realises high-resolution ranging by collimating laser pulses.

Suggestions for selection and use of collimated lenses

Matching of key parameters

Wavelength range: need to match the wavelength of the light source, UV (200-400nm), visible (400-700nm) or infrared (700nm or more) lens design differences are significant.

Aperture: The aperture needs to be larger than the beam diameter to avoid fringe light loss.

Surface accuracy: High-precision applications (e.g. aerospace optics) require a surface roughness of <5nm, which can be relaxed to λ/4 (λ=633nm) for common industrial scenarios.

Environmental adaptability considerations

In high temperature, high humidity or corrosive environment, quartz material + waterproof coating is preferred.

Frequent vibration scenes need to be matched with anti-vibration mounts to prevent lens deflection.

Maintenance and Calibration

Regularly clean the mirror surface with a dust-free cotton swab dipped in ethanol and avoid scratching with hard objects.

Use interferometer or parallel light tube to detect the performance of the lens and adjust the installation angle in time.

4. Industry Development Trend and Innovation Direction

Ultra-surface lens technology

Nano-structured super-surface lenses (Metalens) can replace traditional curved lenses to achieve a thinner and lighter design and maintain high performance over a wide wavelength band, which is expected to be applied to AR/VR devices.

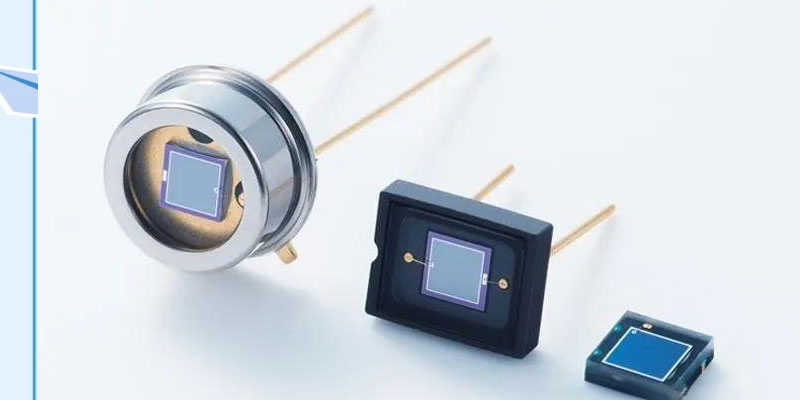

Intelligent Integration Solutions

Combining sensors and auto-tuning algorithms to develop an adaptive collimation system that compensates in real time for light path shifts caused by temperature, vibration, and other factors, to meet the flexible production needs of Industry 4.0.

Cost Optimisation and Domestic Substitution

With the breakthrough of domestic optical processing technology, the domestic collimating lens is close to the international level in terms of coating uniformity, consistency and other indicators, and the price is 30%-50% lower than that of imported products, which promotes the downstream industry to reduce costs and increase efficiency.

Collimating lenses are key components in optical systems that enable light to travel in a predetermined way by changing the direction and shape of the light beam. With the development of optical technology, the design and application of collimating lenses are also advancing, providing powerful support for modern optical devices.

optlenses

Related Blogs