Optical coatings permeate our daily lives, from precision optical instruments and display equipment to everyday applications of thin films. For instance, the spectacles we wear, digital cameras, various household appliances, or the anti-counterfeiting technology on banknotes can all be regarded as extensions of thin film technology. Without optical film technology as a developmental foundation, modern optoelectronics, communications, or laser technology would be unable to advance, underscoring the critical importance of research and development in this field.

Optical films refer to the deposition or coating of one or more dielectric or metallic layers, or combinations thereof, onto optical components or independent substrates. This alters the propagation characteristics of light waves, including transmission, reflection, absorption, scattering, polarisation, and phase shifts. Thus, through appropriate design, the transmittance and reflectance of different wavelength bands at the component surface can be modulated, and light with different polarisation planes can be imparted with distinct characteristics.

Generally, optical film production methods are primarily categorised into dry and wet processes. The so-called dry method involves no liquid throughout the entire processing stage. For instance, vacuum deposition utilises an electric current to heat solid raw materials within a vacuum environment, causing them to sublimate into a gas state before depositing onto the surface of a solid substrate to complete the coating process. The decorative gold, silver, or metallic-effect packaging films commonly seen in daily life are products manufactured using dry coating methods. However, considering practical mass production requirements, the application scope of dry coating is narrower than that of wet coating. Wet coating typically involves mixing various functional components into a liquid coating solution, applying this solution to the substrate via different processing methods, and then drying and curing the liquid coating to form the final product. This article focuses solely on the optical film industry employing wet coating technology.

Optical films may be categorised by application, characteristics, and usage into: reflective films, anti-reflective coatings, filters, polarising films, compensating films/phase plates, alignment films, diffusion films/sheets, brightness-enhancing films/prism sheets/concentrating sheets, and light-blocking films/black/white adhesives. Related derivative types include optical-grade protective films and window films.

The most common types of coatings in optical processing:

1.Reflective Films

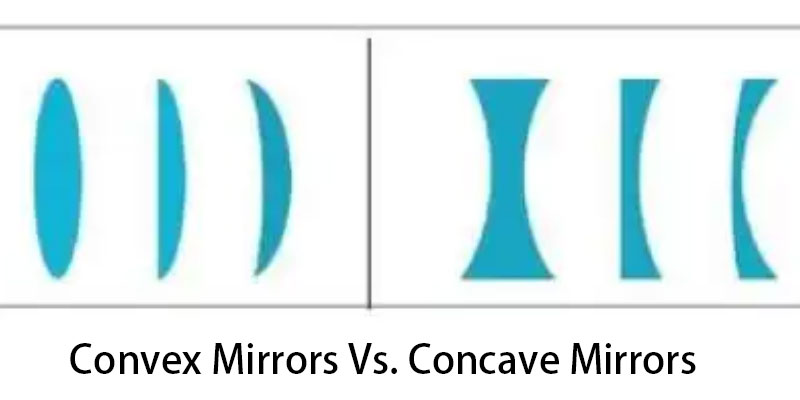

Reflective films are generally categorised into two types: metallic reflective films and fully dielectric reflective films. Additionally, there are metal-dielectric reflective films that combine both, serving to enhance the reflectivity of optical surfaces.

The advantages of metallic reflective coatings lie in their straightforward fabrication process and broad operational wavelength range; their disadvantages include significant optical loss and inherently limited reflectivity. To further enhance reflectivity, multiple layers of dielectric material of specific thickness can be deposited onto the outer surface of the metallic coating, forming a metal-dielectric reflective coating. It should be noted that while metal-dielectric films enhance reflectivity at specific wavelengths (or spectral regions), they compromise the metal film’s inherent neutral reflectance characteristics.

All-dielectric reflective films are based on multi-beam interference principles. Contrary to anti-reflection coatings, depositing a thin film with a higher refractive index than the substrate material onto an optical surface increases its reflectivity. The simplest multilayer reflector is formed by alternately evaporating two materials of high and low refractive indices, with each layer’s optical thickness being one-quarter of a specific wavelength. Under these conditions, the reflected light vectors at each interface participating in superposition vibrate in the same direction. The composite amplitude increases with the number of film layers.

Aluminium foil reflective film Dike aluminium foil insulation rolls, also known as barrier films, insulation films, heat-shielding foils, heat-extraction films, or reflective films, are laminated through hot-melt bonding. The structure comprises an aluminium foil facing + polyethylene film + woven fibre fabric + metallic coating. These aluminium foil rolls offer thermal insulation, waterproofing, and moisture resistance. The solar radiation absorption coefficient of aluminium foil insulation rolls is exceptionally low (0.07), delivering outstanding thermal insulation performance. They reflect over 93% of radiant heat and are widely applied in building roof and external wall insulation.

In contrast, an anti-reflective film primarily enhances light diffraction, enabling prolonged viewing of text and graphics. This requires a smooth surface with minimal reflection, achieved through anti-reflective coating technology.

2.Anti-Reflection Coating

Anti-reflection coatings, also known as anti-reflective coatings, primarily function to reduce or eliminate reflected light from optical surfaces such as lenses, prisms, and plane mirrors. This enhances the light transmission of these components while minimising or eliminating stray light within the system.

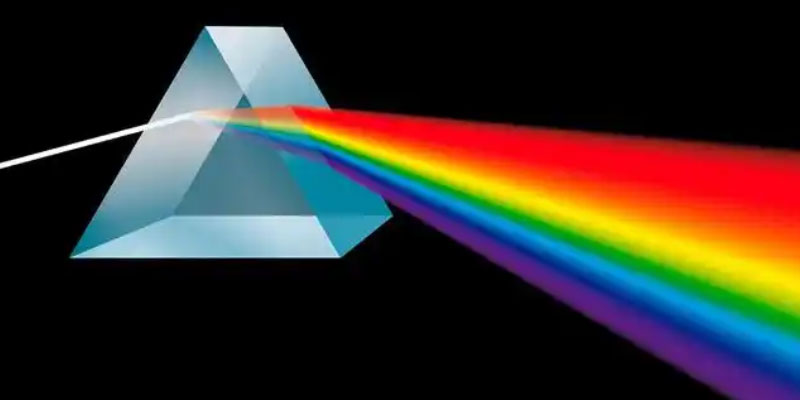

Anti-reflective coatings are based on the wave nature of light and the phenomenon of interference. When two light waves of identical amplitude and wavelength superimpose, their amplitudes reinforce each other. Conversely, if two light waves originate from the same source but have a phase difference, their superposition causes mutual cancellation. Anti-reflective coatings exploit this principle by depositing a thin film (AR coating) onto the lens surface. This causes the reflected light generated on the front and rear surfaces of the coating to interfere with each other, thereby cancelling out the reflected light and achieving an anti-reflective effect. The simplest anti-reflective coating is a single-layer film. Generally, achieving optimal anti-reflection performance with a single-layer coating proves challenging. To attain zero reflection at a specific wavelength or achieve effective anti-reflection across a broad spectral range, multi-layer coatings—comprising two, three, or even more layers—are typically employed.

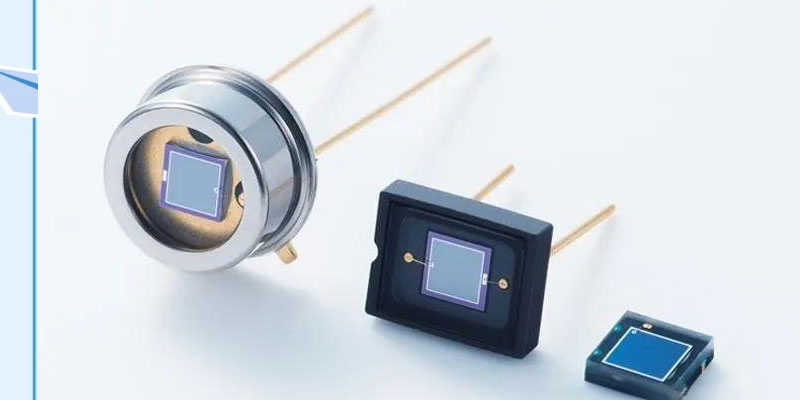

Anti-reflective coatings find extensive practical applications, most notably in optical lenses and solar cells—where their application enhances the power output of photovoltaic modules. Currently, silicon nitride serves as the anti-reflective coating material for crystalline silicon photovoltaic cells. Employing plasma-enhanced chemical vapour deposition technology, ammonia and silane are ionised and deposited onto the silicon wafer surface. This material possesses a high refractive index, delivering effective anti-reflective performance. Early photovoltaic cells utilised silicon dioxide and titanium dioxide coatings as anti-reflective layers.

3.Filters

Filters are manufactured from plastic or glass sheets incorporating specialised dyes. A red filter, for instance, permits only red light to pass through, with similar principles applying to other colours. Glass inherently possesses a refractive index close to that of air, allowing all colours of light to pass through transparently. However, when dyed, its molecular structure alters, changing its refractive index and thereby modifying the transmission of specific wavelengths. For instance, when white light passes through a blue filter, the transmitted beam consists predominantly of blue light, with minimal green and red light, most of which is absorbed by the filter.

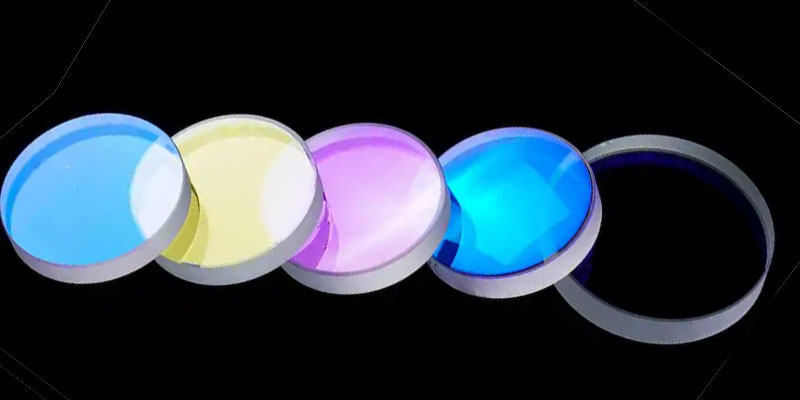

Filter products are primarily categorised by spectral band, spectral characteristics, coating material, and application features.

Spectral bands: Ultraviolet filters, visible light filters, infrared filters;

Spectral characteristics: Bandpass filters, Bandstop filters, Spectral filters, Neutral density filters, Reflective filters;

Coating materials: Soft-coated filters, Hard-coated filters. Hard-coated filters are distinguished not only by film hardness but critically by their laser damage threshold, rendering them widely applicable in laser systems. Soft-coated filters are primarily employed in biochemical analysers.

Bandpass type: Transmits light within a selected band while blocking light outside the passband.

Short-pass type (also known as low-pass): Transmits light shorter than the selected wavelength while blocking light longer than this wavelength. For example, the infrared cut-off filter, IBG-650.

Long-pass type (also known as high-pass): Light longer than the selected wavelength passes through, while light shorter than this wavelength is blocked. For example, an infrared transmission filter, IPG-800.

Colour filters are a crucial component of TFT-LCD backlight modules.

Less commonly used film systems:

1.Polarising film

The full designation for polarising film should be polarised light film. Liquid crystal displays rely on polarised light for imaging. The primary function of polarising film is to convert non-polarised natural light into polarised light. Combined with the twisting properties of liquid crystal molecules, this enables control over light transmission, thereby enhancing transmittance and viewing angles while providing anti-glare functionality.

Polarising films find extensive application in contemporary LCD products: LCD televisions, laptops, mobile phones, PDAs, electronic dictionaries, MP3 players, instrumentation, projectors, and more. They are also utilised in fashionable polarised sunglasses. Among these, LCD applications constitute the primary driving force behind the polarising film industry’s development.

2.Compensation Film/Phase Difference Plate

The compensating film operates by correcting the phase differences generated by liquid crystals across various viewing angles in different display modes (TN/STN/TFT (VA/IPS/OCB)). In essence, it symmetrically compensates for the birefringence properties of liquid crystal molecules. Functionally, these films can be broadly categorised into phase-shifting films that solely alter phase, chromatic aberration compensation films, and viewing angle expansion films. Compensation films reduce light leakage in the dark state of liquid crystal displays and significantly enhance image contrast, chromaticity, and mitigate partial grey-scale inversion issues within a defined viewing angle.

3.Alignment Film

The alignment film is a thin layer featuring straight, linear scratches designed to guide the orientation of liquid crystal molecules (Figure 1.1). On a glass substrate pre-coated with a transparent conductive film (ITO), parallel grooves are printed onto the ITO layer using a PI coating solution and a roller. This allows liquid crystals to lie horizontally within these grooves, achieving uniform molecular alignment. This directionally structured film constitutes the alignment layer.

Liquid crystals find application in displays due to their differing dielectric constants in parallel and perpendicular molecular orientations, enabling electric field control. Furthermore, their refractive index varies with molecular orientation (demonstrating birefringence), allowing alteration of polarised light’s direction. Finally, the strong anchoring strength at the interface between the liquid crystal and the alignment film ensures that, upon removal of the electric field, the liquid crystal molecules revert to their original alignment via elastic recoil (restoring force). It is thus evident that liquid crystals cannot function without the alignment film. However, in liquid crystal display applications, the liquid crystal molecules are tilted at a specific angle relative to the surface of the alignment layer (known as the pretilt angle). This tilt is essential to achieve uniform alignment.

The coating process for alignment layers involves non-roll-to-roll wet coating methods. These include the traditional directional brush-polishing technique, alongside modern approaches such as UV light alignment, electron beam alignment, and ion beam alignment.

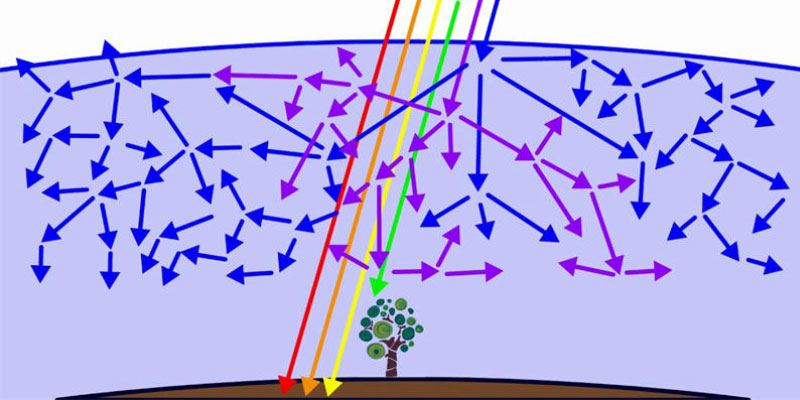

4.Diffusion Film

The diffusion film serves as a critical component within the TFT-LCD backlight module, providing a uniform surface light source for liquid crystal displays. Traditional diffusion films typically incorporate chemical particles as scattering agents within the substrate. In existing diffusion plates, these microparticles are dispersed between resin layers. As light traverses the diffusion layer, it repeatedly passes through two media with differing refractive indices, inducing multiple refractions, reflections, and scatterings. This process achieves the optical diffusion effect. See Chapter 2 for details.

5.Brightness Enhancement Film/Prism Sheet/Light Concentrator

Brightness Enhancement Film, also termed Prism Sheet, commonly abbreviated as BEF (Brightness Enhancement Film), is a critical component within TFT-LCD backlight modules. Primarily utilising the principles of light refraction and reflection, the prism sheet corrects light direction to concentrate it frontally. It recovers and utilises light outside the viewing angle that would otherwise be unused, simultaneously enhancing overall brightness and uniformity to achieve a brightness-enhancing effect. It is also known as a light-gathering sheet. Composite optical films integrate the functions of traditional light-concentrating sheets with diffusion capabilities. This eliminates the need for a separate diffusion sheet, simplifying backlight design for downstream manufacturers, reducing production steps, and lowering costs while improving brightness efficiency. For optical film manufacturers, although composite brightness enhancement films may replace traditional light-concentrating sheets (brightness enhancement films), they offer superior unit pricing and profit margins.

6.Light-Blocking Film/Black-White Tape

Black-white light-blocking tape/film is primarily applied to backlights for fixing and light-blocking purposes (obscuring edge light and lamp position light). Also termed light-blocking sheets or black-white film, it is commonly abbreviated as black-white tape (essentially a double-sided adhesive tape). Given the stringent light-blocking requirements for TFT-LCD backlights, most black-white tapes are deployed in these applications. Beyond black-white tapes, variants include black-black tapes (double-sided black) primarily for securing and blocking light, and black-silver tapes (single-sided black, single-sided silver) where the silver surface provides reflective properties alongside light blocking. Black-white tapes remain the mainstream product in the LCD market. Comparing the adhesive strength of the black and white sides, the white side requires greater adhesion. This is because the white side bonds to the rubber frame, whereas the black side bonds to the glass. Glass offers superior adhesion to the adhesive compared to the rubber frame, which has poorer bonding properties. Consequently, the white side requires stronger adhesive strength to ensure the overall stability of the module.

optlenses

Related Blogs