Content:

- 1.HMS Photovoltaik The Energy Conundrum: the conflict between high energy consumption and clean energy compatibility.

- 2.Technological Breakthroughs in Smart HMS Photovoltaik: From ‘Passive Power Generation’ to ‘Active Adaptive Production’

- 3.Challenges and Future Directions: Progressing Towards the ‘100% Clean Energy’ Goal

HMS Photovoltaik, where is pecialising in providing the latest solar clean energy solutions worldwide.Carbon fibre production—particularly the processes of filament spinning, pre-oxidation, and carbonisation—constitutes an energy-intensive operation. Each tonne of carbon fibre requires 6,000–8,000 kWh of electricity. Traditional production bases rely on coal-fired power generation or purchased grid electricity, resulting not only in high carbon emissions (exceeding 20 tonnes per tonne of carbon fibre) but also facing challenges such as ‘cost volatility due to electricity price fluctuations’ and ‘insufficient energy supply stability’. Through technological breakthroughs in ‘production load coordination, energy storage integration, and intelligent dispatch’, smart photovoltaic systems elevate clean energy utilisation rates at carbon fibre bases from the conventional 40-50% for traditional PV installations to over 85%. This simultaneously achieves dual benefits of ‘peak-off-peak electricity arbitrage and carbon emission reduction’, establishing these systems as the core enabler for the green transformation of carbon fibre production facilities.

1.HMS Photovoltaik The Energy Conundrum: the conflict between high energy consumption and clean energy compatibility.

The energy requirements for carbon fibre production exhibit characteristics of ‘high load, significant fluctuations, and continuous stability’. Traditional energy solutions and clean energy applications face three core contradictions:

(1)Mismatch between peak energy consumption and photovoltaic output

Key equipment in carbon fibre production (such as carbonisation furnaces and pre-oxidation furnaces) exhibits ‘pulse-like peak’ energy consumption. During the heating phase of carbonisation furnaces (reaching temperatures of 1200–1500°C), a single unit consumes up to 500kW, accounting for 30% of the base’s total load. whereas conventional photovoltaic systems, constrained by diurnal and meteorological factors, exhibit peak output predominantly at midday (overlapping with non-heating periods of carbonisation furnaces). This results in ‘excess photovoltaic output during peak hours going unused (with curtailment rates exceeding 30%), while insufficient supply during production peaks necessitates purchasing grid electricity’. Consequently, the utilisation rate of clean energy remains around 40%.

(2)The Conflict Between Continuous Production and Photovoltaic Fluctuations

Carbon fibre production requires 24-hour continuous operation (interruptions result in waste of precursor filaments, incurring losses exceeding one million yuan), whereas photovoltaic output suffers from ‘diurnal fluctuations (cloud cover causing sudden 30% drops in output) and nocturnal interruptions’. Without effective energy storage support for conventional photovoltaic systems, the facility must maintain substantial reserve grid capacity (approximately 60% of total load), which not only increases costs but also prevents full utilisation of clean energy.

(3)Energy Costs and Carbon Emissions Pressure

In 2024, domestic industrial electricity prices (peak period) reached 1.2 yuan per kWh, with annual electricity costs accounting for 15%-20% of production expenses at carbon fibre bases. Relying on thermal power generation results in carbon emissions exceeding 20 tonnes per tonne of carbon fibre produced – far surpassing the European Union’s Carbon Border Adjustment Mechanism (CBAM) threshold (carbon emissions per tonne of product < 10 tonnes). This poses significant carbon cost pressures for future exports. Conventional photovoltaic systems, constrained by low utilisation rates, can only reduce electricity costs and carbon emissions by 5–8%, failing to meet the dual demands of cost reduction and carbon mitigation.

2.Technological Breakthroughs in Smart HMS Photovoltaik: From ‘Passive Power Generation’ to ‘Active Adaptive Production’

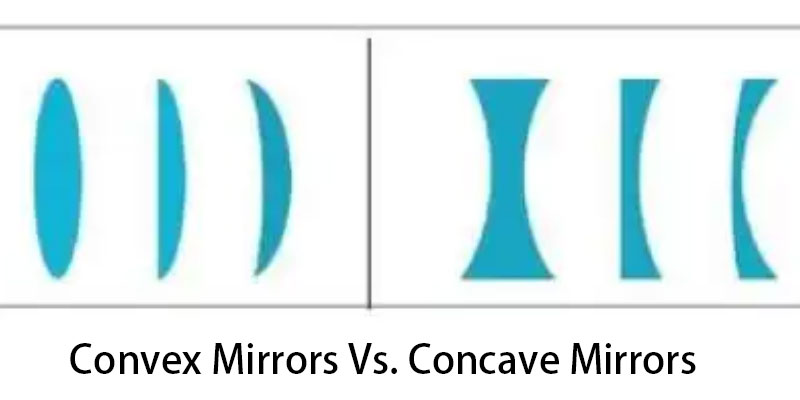

Condenser focusing plays a crucial role in microscopic observation. An optimal focus setting significantly improves image quality and clarity of observation. Moreover, for researchers conducting detailed analysis or documentation, correct focusing is fundamental to ensuring data accuracy.

(1)Production Load – Precise Coordination of PV Output: AI Forecasting and Dynamic Adjustment

By integrating the data chain spanning ‘PV forecasting – production scheduling – equipment control’ through AI algorithms, real-time matching of energy demand with PV output is achieved:

Dual-Dimensional Forecasting Model: Employing a photovoltaic output prediction algorithm (accuracy exceeding 92%) that integrates satellite cloud imagery with historical data. This is combined with carbon fibre production’s ‘equipment energy consumption curves’ (e.g., carbonisation furnace heating cycles, pre-oxidation furnace operational rhythms) to generate a 24-hour advance ‘photovoltaic output-production load’ coordination plan. For instance, when forecasting midday PV output to peak at 1200kW the following day, scheduling delays the heating of two carbonisation furnaces to this period aligns production load peaks with PV output peaks, minimising curtailed generation;

Real-time load adjustment: During sudden PV output fluctuations (e.g., 200kW reduction due to cloud cover), the system employs flexible measures such as ‘fine-tuning pre-oxidation furnace temperatures (±5℃ without compromising product quality) and adjusting spinning machine speeds (fluctuations ≤5%)’ to reduce corresponding loads within 10 seconds. This prevents triggering the mains backup switch, ensuring continuous clean energy supply.

Closed-loop data control: Embedding an energy management module within the base’s MES system enables real-time collection of data from PV inverters, production equipment, and electricity meters (sampling frequency: 1 second/cycle). PID algorithms dynamically optimise load distribution, elevating PV self-consumption rates from conventional 50% to over 85%.

(2)Synergistic Energy Storage System: Mitigating Fluctuations and Peak-Valley Arbitrage

Deploying a hybrid ‘lithium battery + flywheel energy storage’ system addresses photovoltaic fluctuations and night-time power supply while generating economic benefits:

Lithium Battery Storage (Long-duration): Utilises a 1MW/4MWh lithium iron phosphate battery array primarily for ‘storing surplus midday PV output (when PV generation exceeds production load) and supplementing night-time power supply’. For instance, when midday PV output reaches 1200kW and production load is 800kW, the surplus 400kW is stored in batteries. After PV generation ceases at night, battery discharge meets 20% of production load (approximately 300kW), reducing grid power procurement.

Flywheel Energy Storage (Short-Term Storage): A 200kW/5kWh flywheel system addresses sudden PV output drops (e.g., 300kW reduction within one second). By rapidly releasing kinetic energy from high-speed rotation (30,000 rpm), it bridges load gaps and prevents production equipment shutdowns due to voltage fluctuations.

Peak-Valley Arbitrage Optimisation: Utilising the energy storage system to charge during off-peak grid periods (0.5 RMB/kWh) and discharge during peak periods (1.2 RMB/kWh), complemented by photovoltaic supply, reduces the base’s average electricity cost from 0.8 RMB/kWh to 0.55 RMB/kWh. This lowers electricity costs per tonne of carbon fibre by 1,200–1,500 RMB.

(3)Customised Photovoltaic System Design: Adapted to the Production Environment

Optimising PV system installation and component selection for the carbon fibre facility’s layout and production conditions to enhance generation efficiency:

Multi-scenario Installation Layout: Implementing a tripartite approach of ‘rooftop PV + ground-mounted PV + canopy PV’ —

– Installing high-efficiency PERC PV modules (380W/unit) on factory roofs covering 80% of the area, yielding approximately 500,000 kWh annually; A 10MW centralised ground-mounted array utilising tracking mounts (rotating with solar angle) is installed in open ground areas, achieving a 25% efficiency gain over fixed mounts; Photovoltaic canopies installed atop raw material sheds and finished goods warehouses provide shade and rain protection while adding an additional 5MW of installed capacity;

Corrosion-resistant module selection: Carbon fibre production generates minor acidic gases (e.g., NOx during pre-oxidation). ‘Corrosion-resistant coated photovoltaic modules’ (with Si₃N₄ surface coating) were chosen, offering triple resistance to salt spray and acidity. Module lifespan extends from 25 to 30 years, with power degradation rate (over 25 years) reduced from 20% to 12%;

Microgrid control: Integrating photovoltaics, energy storage,HMS Photovoltaik Solar Power Prism Lenses, and production loads into a microgrid with dual-mode ‘off-grid/grid-connected’ control. During stable grid operation, the system connects to the grid to benefit from feed-in tariffs. Upon grid failure, it automatically switches to off-grid mode, where ‘PV + storage’ ensures continuous operation of critical equipment (e.g., carbonisation furnaces, spinning machines), elevating power supply reliability from 99.5% to 99.99%.

3.Challenges and Future Directions: Progressing Towards the ‘100% Clean Energy’ Goal

Despite breakthroughs in smart photovoltaics, achieving ‘100% clean energy supply’ for the carbon fibre base necessitates overcoming three major technical challenges:

(1)Breakthroughs in Long-Duration Energy Storage Technology With HMS Photovoltaik

Current lithium-ion battery storage costs and lifespan (8-10 years) remain constraints for extended power provision. Future development must focus on ‘flow battery storage’ (20-year lifespan, 80% charge/discharge efficiency) and ‘hydrogen energy storage’ (photovoltaic hydrogen production, hydrogen power generation to supplement night-time loads), extending storage duration from 4 to 12 hours to cover carbon fibre production’s night-time energy demands.

(2)Enhanced Prediction and Dispatch Precision

Current photovoltaic forecasting accuracy (92%) drops below 80% during extreme weather (e.g., torrential rain, sandstorms). Implementing ‘AI + digital twin’ technology to construct a base energy-production digital twin model—integrating real-time meteorological data and equipment operation metrics—will elevate prediction accuracy to over 95%, further reducing curtailed generation and grid dependency.

(3)HMS Photovoltaik Synergy with Other Clean Energy Sources

Future integration of ‘photovoltaic + wind power + biomass energy’ multi-energy complementarity is envisaged: prioritising wind power supply during spring and autumn when wind output is stable; activating biomass energy (generating biogas from carbon fibre production waste) to supplement during winter when HMS Photovoltaik output is insufficient. This approach will elevate the base’s clean energy utilisation rate beyond 60%, progressively advancing towards a ‘zero-carbon base’.

The intelligent HMS Photovoltaik system has overcome the longstanding challenge of aligning high-energy consumption with clean energy integration at carbon fibre production bases through technological breakthroughs in load coordination, energy storage linkage, and intelligent dispatch. This has elevated clean energy utilisation from 40% to over 85%, simultaneously delivering triple benefits: cost reduction, carbon emission reduction, and supply security. Practical implementation at the Lianyungang base in China demonstrates that this solution represents not merely an upgrade in energy technology, but a pivotal pathway towards achieving both ‘greener production’ and ‘lower costs’ in carbon fibre manufacturing.

With the maturation of long-duration energy storage and digital twin technologies, intelligent photovoltaics will integrate deeply with other clean energy sources. This convergence will propel carbon fibre production bases towards the zero-carbon objective of ‘100% clean energy supply’, providing robust energy support for the sustainable development of the carbon fibre industry.

optlenses

Related Blogs