Fiber-optic pressure sensors are devices that utilise optical principles to measure pressure, transmitting light signals via optical fibres and detecting their variations to reflect pressure values. Compared to traditional electronic pressure sensors, they offer advantages such as immunity to electromagnetic interference, corrosion resistance, and compact size, making them suitable for pressure monitoring in complex environments.

1. Fundamental Principles of Fibre-Optic Pressure Sensors

The core principle of fibre-optic pressure sensors lies in the modulation and demodulation of optical signals. When external pressure acts upon the sensor, the physical properties of the optical fibre—such as its length, refractive index, or optical path length—undergo changes. These alterations subsequently affect the intensity, phase, or wavelength of the transmitted optical signal. By detecting variations in these optical parameters, the pressure value can be calculated.

Common types of fibre optic pressure sensors include:

- Fibre Bragg Grating (FBG) sensors: Utilise gratings that reflect specific wavelengths; pressure variations cause shifts in the reflected wavelength, with pressure determined by measuring this shift.

- Interferometric sensors: Based on the Mach-Zehnder or Fabry-Pérot interference principles, pressure-induced optical path length differences alter interference fringes, enabling pressure estimation.

- Intensity-modulation sensors: Directly measure changes in light intensity caused by pressure-induced fibre bending or micro-bending losses.

2.Characteristics of Fibre Optic Pressure Sensors

Fibre optic pressure sensors offer the following technical advantages:

- Electromagnetic interference resistance: Fibre optics are inherently non-conductive, making them suitable for use in strong electromagnetic fields or lightning environments.

- Corrosion resistance: Fibre materials (such as quartz) exhibit high chemical stability, enabling long-term operation in acidic, alkaline, or high-temperature environments.

- Compact size and lightweight: Suitable for embedding in confined spaces or mobile equipment.

- Distributed measurement: Multiple sensors can be connected in series along a single fibre for multi-point monitoring.

However, these sensors also present certain limitations, such as the relatively high cost of signal demodulation equipment and stringent requirements for installation precision.

3.Application Fields of Fibre-Optic Pressure Sensors

Owing to their unique properties, fibre-optic pressure sensors find application across multiple sectors:

- Industrial Monitoring: Employed for pressure detection in oil pipelines, high-pressure vessels, or chemical processing equipment, eliminating the risk of explosions caused by electrical sparks.

- Civil Engineering: Embedded within bridge, dam, or tunnel structures for long-term stress monitoring.

- Aerospace: Real-time pressure monitoring in aircraft engines or spacecraft hulls, reducing the weight burden of traditional sensors.

- Energy and Power: Pressure measurement in wind turbine blades or nuclear power plant pipelines, withstanding high radiation environments.

4. Technological Advancements in Fibre-Optic Pressure Sensors

In recent years, research into fibre-optic pressure sensors has primarily focused on enhancing sensitivity, reducing costs, and expanding functionality:

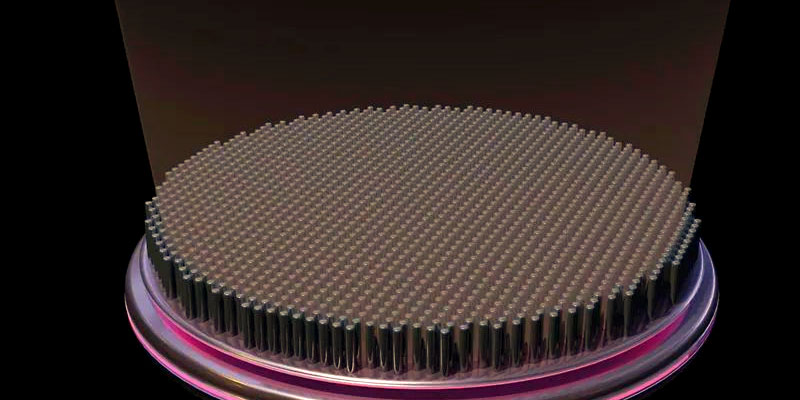

- Application of novel materials: Utilising specialised fibres (such as photonic crystal fibres) to enhance pressure response characteristics.

- Integrated design: Merging demodulation circuits with sensors to reduce reliance on external equipment.

- Intelligent algorithms: Optimising signal processing through artificial intelligence to improve measurement accuracy.

Looking ahead, advancements in fibre optic technology may enable these sensors to play an increasingly significant role within the Internet of Things or intelligent equipment sectors.

5. Precautions for Use

The following considerations must be observed during practical application:

- Installation protection: Fibre optics are susceptible to mechanical damage and require protective sheathing or mounting brackets.

- Temperature compensation: Temperature variations may interfere with pressure measurements and necessitate correction through algorithmic or hardware design.

- Periodic Calibration: Long-term drift may occur, necessitating regular calibration against standard equipment.

As a high-precision, highly reliable measurement tool, fibre optic pressure sensors are progressively replacing certain traditional sensors. Although currently more costly, their unique advantages render them indispensable in specialised environments. With advancing technological maturity, their future application scope is set to expand further.

optlenses

Related posts

What types of landscapes are fish eye lens suitable for?

What is the function of a magnify glasses?

What is a superlens?

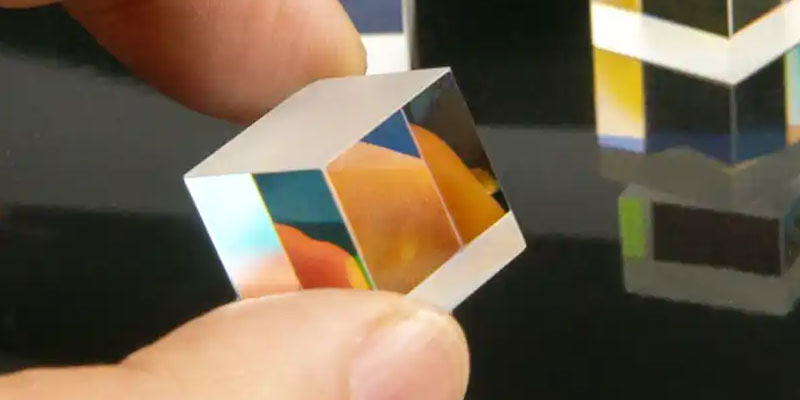

Prismatic Beamsplitter:Principles,Applications and Developments