Optical glass molding method for manufacturing optical parts has the following advantages:

① No need for the traditional rough grinding, fine grinding, polishing, grinding edge centering and other processes, so that the parts can achieve a high degree of dimensional accuracy, face shape accuracy and surface roughness;

② can save a lot of production equipment, tooling accessories, plant area and skilled workers, so that a small workshop can have high productivity;

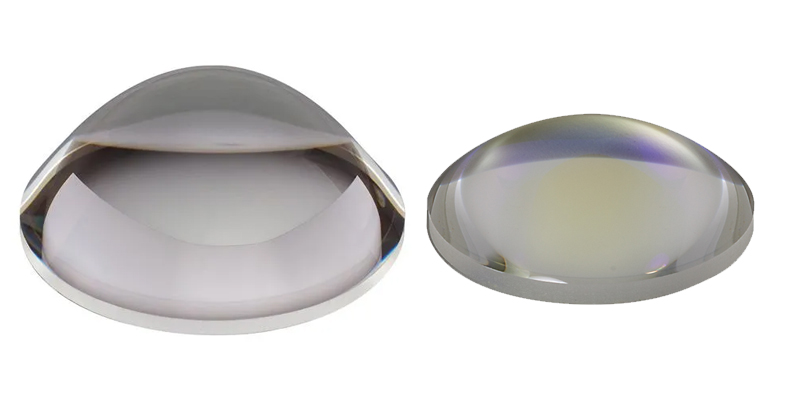

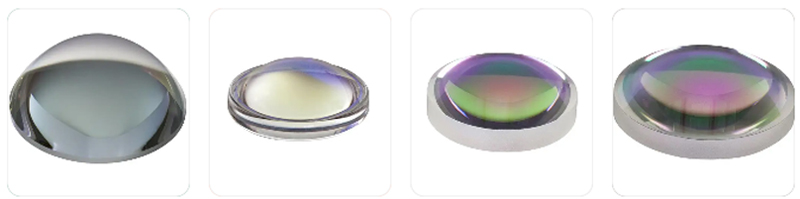

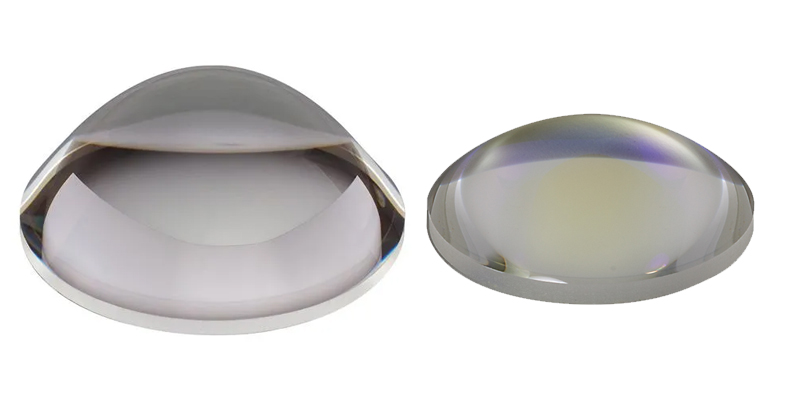

③ The mass production of precision aspheric optical parts can be easily and economically realized;

④ As long as the temperature and pressure and other process parameters in the molding process are precisely controlled, the dimensional accuracy and repeatability of the molded optical parts can be guaranteed;

⑤ Small aspherical lens arrays can be molded;

⑥ Optical parts and mounting reference parts can be made as a whole.

The current mass production of molded aspheric optical parts of the diameter of 2 ~ 50mm, diameter tolerance of ± 0.01mm; thickness of 0.4 ~ 25mm, thickness tolerance of ± 0.01mm; radius of curvature of up to 5mm; surface accuracy of 1.5λ, surface roughness in line with the U.S. military standard of 80-50; refractive index can be controlled to ± 5 × 10-4mm, refractive uniformity can be made as a whole. 4mm, refraction uniformity can be controlled to <5×10-6mm; birefringence is less than 0.01λ/cm.

More details to contact us.

optlenses

Related posts

What is the difference in the reflective and transmission?

What is The Collimating Mirror?

What is The Dove Prism Lens?

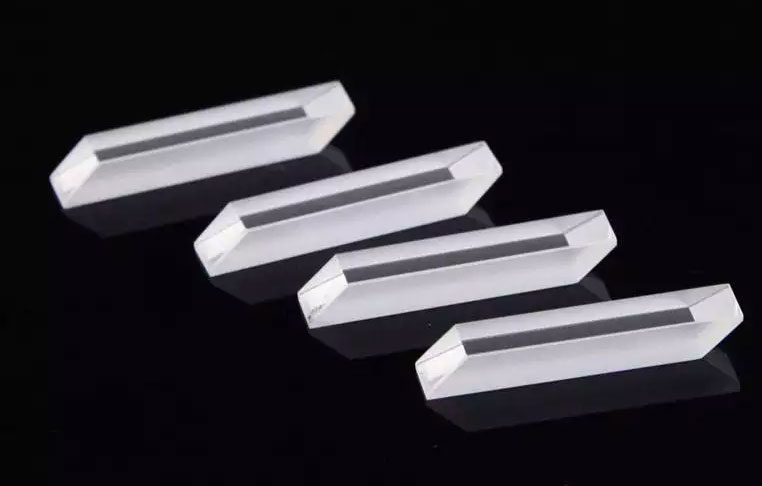

What is The Trapezoidal Lens (Dawe prisms)?