Optical glass molding method for manufacturing optical parts has the following advantages:

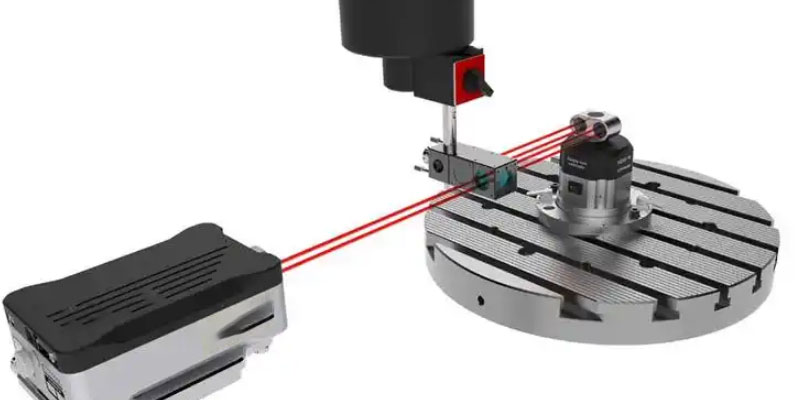

① No need for the traditional rough grinding, fine grinding, polishing, grinding edge centering and other processes, so that the parts can achieve a high degree of dimensional accuracy, face shape accuracy and surface roughness;

② can save a lot of production equipment, tooling accessories, plant area and skilled workers, so that a small workshop can have high productivity;

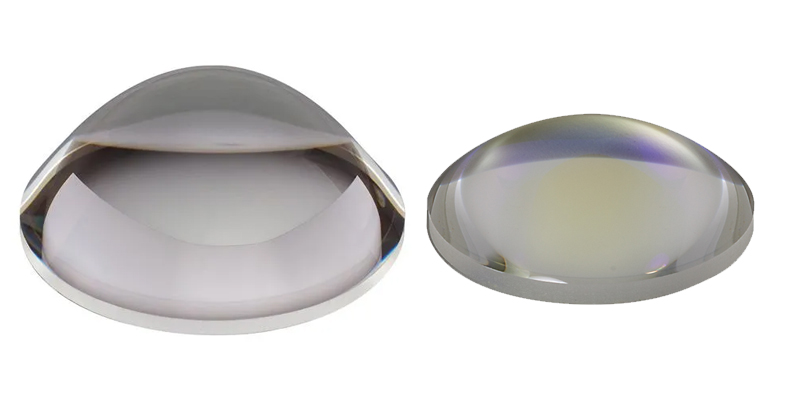

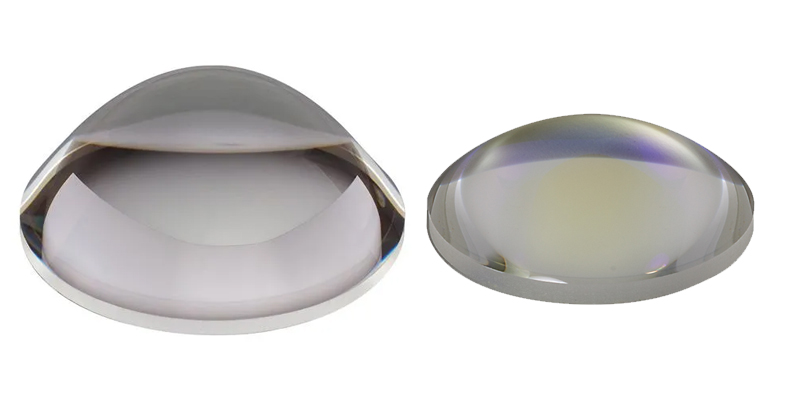

③ The mass production of precision aspheric optical parts can be easily and economically realized;

④ As long as the temperature and pressure and other process parameters in the molding process are precisely controlled, the dimensional accuracy and repeatability of the molded optical parts can be guaranteed;

⑤ Small aspherical lens arrays can be molded;

⑥ Optical parts and mounting reference parts can be made as a whole.

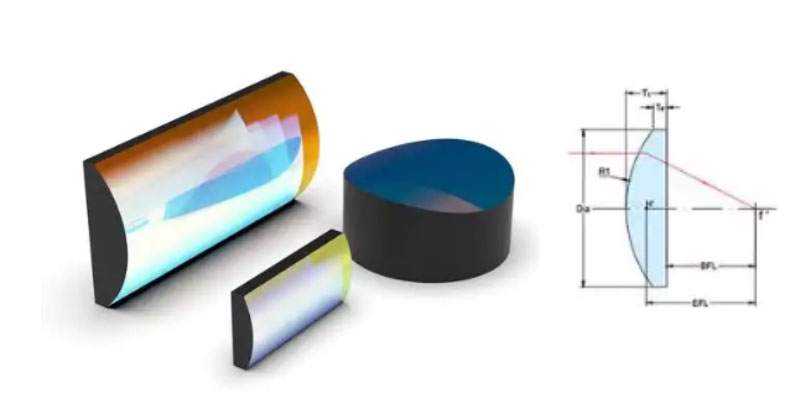

The current mass production of molded aspheric optical parts of the diameter of 2 ~ 50mm, diameter tolerance of ± 0.01mm; thickness of 0.4 ~ 25mm, thickness tolerance of ± 0.01mm; radius of curvature of up to 5mm; surface accuracy of 1.5λ, surface roughness in line with the U.S. military standard of 80-50; refractive index can be controlled to ± 5 × 10-4mm, refractive uniformity can be made as a whole. 4mm, refraction uniformity can be controlled to <5×10-6mm; birefringence is less than 0.01λ/cm.

More details to contact us.

optlenses

Related posts

What is the group velocity dispersion?

Cylinder Lens:The Function and Application Areas

What is The Interferometers?

Dichroic Mirror: A Reliable Assistant in Gemstone Identification