Types of Optical Glass and Blanks

Optics Glass blanks are directly related to the quality of molded products. By definition, most optical glass can be molded into molded products. However, glass with a high softening point, due to the high molding temperature, reacts slightly with the mold, resulting in a short service life of the mold. Therefore, from the point of view of easy selection of mold materials and extension of mold service life, it is necessary to develop glass suitable for molding at low temperatures (around 600°C). However, the glass developed for low-temperature molding must meet the requirements of being able to manufacture blanks inexpensively and not containing substances that pollute the environment (e.g., PbO, As2O3). The use of molding glass blanks are required:

① before pressing the surface of the blank must be kept very smooth and clean;

② is the appropriate geometric shape;

③ there is a need for capacity. Blanks are generally selected spherical, pancake or spherical shape, using cold grinding molding or hot press molding.

Application of Glass Molding Technology

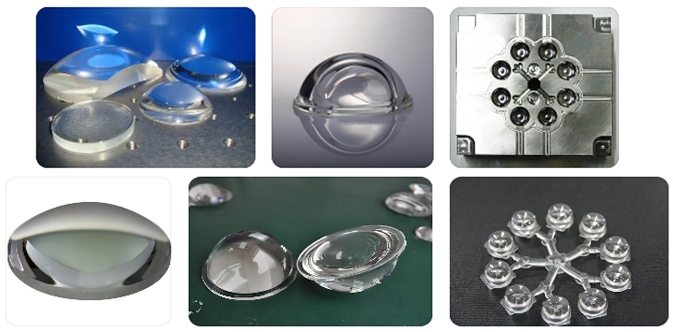

At present, optical glass lens molding technology has been used to mass produce precision spherical and aspherical lenses. Normally, in addition to the general production and manufacture of lenses with a diameter of about 15mm, it is also possible to produce and manufacture large-diameter lenses with a diameter of 50mm, miniature lens arrays, and so on. It is now possible to manufacture microlens arrays with a diameter of 100μm for each lens.

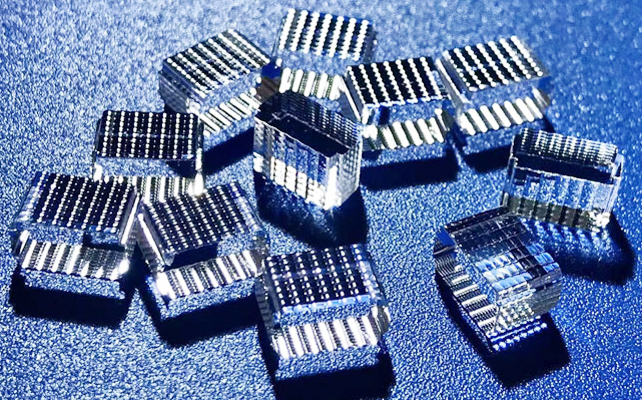

①Manufacture of spherical and aspherical optical parts used in military and civilian optical instruments, such as lenses, prisms, and filters;

② Manufacture of aspherical lenses for fiber optic couplers for optical communications;

③ Aspherical lenses for concentrating light for optical disks. The use of a molded aspheric lens manufactured by the molding method can be used in place of three spherical lenses used in the optical lens of the optical disc reader. Due to the high precision of molded aspherical lens, not only can control and correct the axial aberration of the large numerical aperture, but also the weight of the original optical lens to reduce the weight and cost by 30 to 50%.

④Manufacture of aspherical lenses for camera viewfinders, movie projectors, and camera lenses.

optlenses

Related posts

What Does The Condenser Do On A Microscope?

What Is An Adjustable Diaphragm On A Mobile Phone?

What is Fiber-optic Pressure Sensors?

What is Optical Burst Switching?